Difference between IQF and Blast freezing

IQF vs. Blast Freezing: A Comprehensive Guide to Freezing Technologies in the Food Industry

Overview

Freezing technologies are essential in preserving food quality, extending shelf life, and ensuring safe distribution. Two prominent methods are Individually Quick Freezing (IQF) and Blast Freezing. Both serve different purposes depending on product type, volume, and end-use. Understanding their processes and effects can help producers and buyers make informed decisions.

What is IQF (Individually Quick Freezing)?

IQF is a modern freezing technique designed to freeze individual food pieces—such as fruits, vegetables, seafood, or pasta—rapidly and separately. This process prevents clumping, maintains natural appearance, and preserves texture and nutrients.

SEO Keywords: IQF, IQF freezing process, IQF vegetables, IQF fruits, frozen food technology, best food preservation methods

How Does IQF Freezing Work?

- Preparation – Food is washed, sorted, peeled, or cut as needed.

- Blanching (optional) – Brief hot water or steam treatment helps retain color and nutrients in vegetables.

- Freezing Tunnel – Items are passed through ultra-cold air (-40°C) in a tunnel or fluidized bed, ensuring rapid, even freezing.

- Anti-Clumping Effect – Each item is frozen individually, avoiding bulk clumps.

- Quality Control – Inspections remove defects or inconsistencies.

- Packaging – Frozen products are packed in retail or bulk bags.

- Storage – Maintained below -18°C in cold storage until distribution.

Benefit: IQF keeps food items separate, visually appealing, and easy to portion.

Impact of IQF on Food Quality

- Texture: Preserves structure by avoiding large ice crystals

- Flavor: Maintains original taste and moisture

- Nutrition: Retains vitamins and minerals due to faster freezing

- Visuals: Food holds its shape, color, and gloss

Common IQF Products:

IQF strawberry, IQF mango chunks, IQF green beans, IQF broccoli, IQF cauliflower, IQF shrimp, IQF peas, and IQF mixed vegetables

What is the Purpose of IQF?

- Preserve natural texture and flavor

- Simplify portion control and usage

- Extend shelf life without added preservatives

- Reduce waste by allowing selective use

- Improve product appeal in retail and foodservice markets

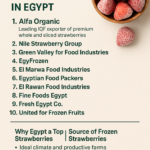

At Alfa Organic, we offer premium IQF fruits and vegetables with top quality and competitive prices for global export.

What is Blast Freezing?

Blast freezing is a traditional method used to freeze large quantities of food using high-velocity cold air. It operates between -30°C and -40°C and is ideal for mass production.

SEO Keywords: Blast freezing, blast freezing process, food freezing comparison, food industry preservation

Blast Freezing Process

- Preparation – Food is cleaned and prepped.

- Tray Loading – Food is placed on trays or racks with spacing for airflow.

- Freezing Chamber – Cold air circulates to rapidly freeze the items.

- Temperature Monitoring – Ensures core temp reaches -18°C or lower.

- Packaging – Once frozen, food is packed and labeled.

- Storage – Transferred to long-term cold storage facilities.

Key Strengths: Effective for freezing large volumes efficiently at low cost.

Impact of Blast Freezing on Food Quality

- Texture: Larger ice crystals may affect softness or firmness

- Flavor: Minor changes due to cell rupture

- Nutrition: Slight loss of heat-sensitive vitamins

- Clumping: Items may freeze together in bulk

IQF vs. Blast Freezing: Key Differences

| Feature | IQF Freezing | Blast Freezing |

|---|---|---|

| Freezing Speed | Very fast (individual items) | Fast (bulk items) |

| Product Separation | High – items freeze separately | Low – items may clump |

| Ice Crystals | Minimal (better texture) | Larger (can damage cells) |

| Ideal For | Berries, vegetables, seafood, pasta | Meat, baked goods, bulk freezing |

| Food Quality | High retention of texture, flavor, and nutrients | Moderate quality, may degrade over time |

| Cost | Higher (technology-dependent) | More economical for mass scale |

| Convenience | High – easy portion control | Low – bulk frozen blocks |

Conclusion

IQF and Blast Freezing are both vital in the frozen food industry. IQF is ideal for preserving premium quality and individual usability, making it the best choice for retail-ready fruits and vegetables. Blast freezing, while slightly less refined, offers a cost-effective solution for freezing large food volumes efficiently.

At Alfa Organic, we specialize in delivering high-quality IQF products—from strawberries to mango chunks—with consistent standards and international export capabilities.

Related Topics:

- What does IQF mean in food?

- IQF vs Traditional Freezing

- IQF Fruits and Vegetables from Egypt

- IQF vs Blast Freezing process comparison

- Why choose IQF over traditional freezing methods

- Advantages of IQF for export-quality food